Description

Description

Bearing housings Code: MDH-20,35,40,65,100, WN-06, MDH-forty five, SAE to NEMA, SN-06, SAE to Shaft

EPT builds bearing housing for a very wide range of machines and programs, with shaft speeds from 540 up to 4000 RPM and radial load capacity up to 21 tons. Input can be PTO shaft, tractor, electric motor, hydraulic motor, metric and inch, or shaft input shaft output.

Application:

- Feed Blenders

- Flail Mowers

- Potato Harvesters

- Pump Drives

- Rock Pickers

MD-20 Mower Spindle Bearing Housing

mdh bearing house

Possibilities contain: Aluminum or Casting iron housings proper hand or left hand, Bolts1/2 “or 9/sixteen”, diameter3, 4, 6 bore sample tapered Keyed output and straight keyed output shaft flanges are found in the centre and base housing sealed and unsealed bearings occur normal with 4.5 “pulleys, single groove B kind pulleys are optional with double groove B sort pulleys

mdh bearing home

mdh bearing home

mdh bearing house

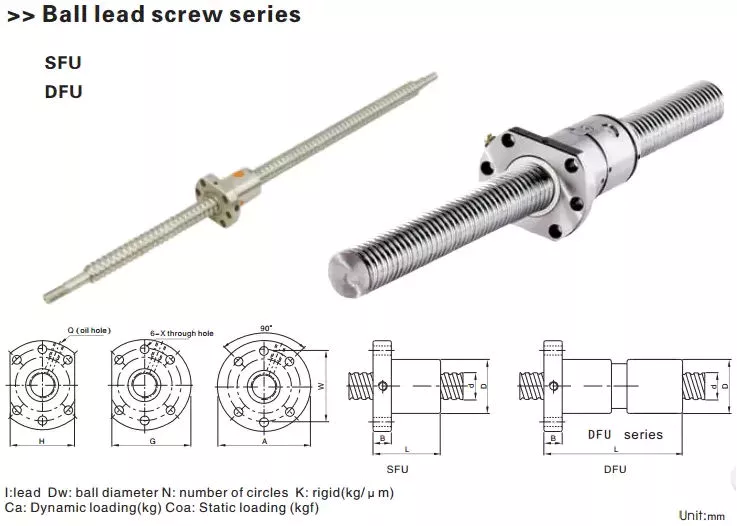

Specifying a Ball Screw

When you need to have a substantial-good quality ball screw, it is critical to decide on 1 with the proper proportions and requirements. When you are seeking for the greatest item, you ought to consider features these kinds of as preloading, surface area complete, and inside return method. You can find out much more about these characteristics in this post. If you happen to be doubtful which kind of ball screw to decide on, get in touch with a trustworthy supplier for further assistance. To find the ideal merchandise for your requirements, click on listed here!

Brinelling

When specifying a Brinelling ball screw, it is vital to know how considerably axial load it can safely bear. The static load capacity, which is presented in the catalogue, applies only to pure axial loading, and any radial load that is smaller sized than 5% of the axial load won’t pose a difficulty. For far more details, get in touch with a CZPT engineer. Brinelling ball screw services existence calculation ought to be executed employing the pursuing information:

Preload: The quantity of load a ball screw can manage throughout a single revolution. Preload is the load used prior to the ball screw begins transferring, and the load is typically among 5 and ten p.c of the dynamic capacity. Even so, a ball screw that is matter to vibration will expertise increased preload, requiring more regular lubrication. The resulting mechanical pressure could cause the ball screw to buckle, or lead to the nut to re-flow into the balls.

Essential ball pace: The optimum velocity at which the ball can transfer by means of the ball nut is named the essential ball speed. In contrast, operating the ball screw at its critical shaft speed can direct to excessive vibrations, foremost to premature failure of the stop assist bearings and brinelling of the ball observe. Hence, it is suggested to work a ball screw at a decrease pace than the crucial ball pace to avoid brinelling and plastic deformation of the balls.

Fake brinelling: Untrue brinelling is a sort of Fretting. Fake brinelling happens when the bearings are not rotating. The motion will result in depressions or use marks in the bearing raceway. This will trigger noise, wear, and eventual fatigue. If these situations persist, a newer ball screw must be employed to test the method. The equipment need to be run for a number of several hours and tested prior to replacing the bearing.

Preloading

The procedure of preloading ball screws minimizes backlash by applying stress to the threads in the opposite path of the screw’s direction of rotation. It prevents any movement of the screw relative to the nut. Various techniques are utilized for preloading. A common a single is to use oversized balls inside of the ball nut. A double nut method may possibly also be utilised. Both approaches are similarly efficient. No matter of the technique utilised, the stop result is the very same – minimal backlash and increased efficiency.

In the standard technique of preloading ball screws, the motors function simultaneously in opposite directions, creating them to have a relative motion of around equivalent magnitudes. This reduces the frictional resistance of the method, ensuing in quick traverse. The system is capable to operate with minimal backlash throughout 110 inches of travel, reducing the heat developed by the drive nuts and the issues linked with ball screw heating. Furthermore, this method can be used in a broad variety of apps.

Another approach of preloading ball screws is acknowledged as the ball-pick method. This strategy consists of the use of over-sized balls that force the balls into much more contacts with the screw and nut than a typical ball screw. The gain of this method is that it decreases backlash since the balls are not machined to substantial tolerances. The disadvantage of this approach is that the ball screw will expense more to manufacture than a common ball screw and nut.

A typical layout involves a mechanical system that makes use of a collection of balls to rotate a shaft. The problem of backlash is exacerbated by the mass of the shaft. The mechanical technique is much more complicated than required and usually demands a whole lot of hard work. The present invention eliminates these issues by offering an enhanced method and apparatus for driving ball screws. This approach supplies a far more effective preload pressure that is dynamically adjustable although the system is working. The strategy can also boost friction and wear.

Inner return technique

There are two various sorts of ball screws. The very first kind is external and the 2nd is inside. The exterior variety uses return tubes that protrude from the ball nut and lengthen earlier mentioned and close to the exterior of the screw. The internal sort employs a single tube that spans the ball keep track of, whilst the more typical design and style makes use of numerous tubes spanning 1.5 to 3.5 ball tracks. The inner method entails a single return tube and many pickup fingers that guide the balls into the tubes.

The external return tube design is an easier, considerably less costly decision. The exterior ball return system has limited area but can handle a broad assortment of shaft diameters and qualified prospects. Even so, its actual physical dimensions can make it incompatible with a lot of higher-velocity purposes. Consequently, mindful thought must be offered to the mounting possibilities. Inside ball return techniques are very best suited for small leads and ball dimensions. Individuals that need a higher speed will likely gain from the external ball return system.

Internal ball screw technological innovation has also stored tempo with the needs of linear push programs. Ball screw technological innovation is now much more resilient than ever. Robust inner ball return programs flow into ball bearings by means of a sound pickup pin. These deflectors help the balls return to the screw in the correct area. They are vital elements in personal computer-managed motion management systems and wire bonding. If you happen to be fascinated in the most current advances in linear screw technologies, contact us today.

Ball screws are excellent to guide screws in numerous ways. Ball screws are much more productive than direct screws, changing 90% of rotational motion into linear movement. As a consequence, they are a lot more costly than direct screws and acme screws. They also offer a smoother movement in excess of the entire travel selection. Additionally, they call for considerably less electrical power for the identical functionality. It really is no wonder that the ball screw is so well-liked in several diverse purposes.

Area finish

The area finish of a ball screw is 1 of the essential aspects in determining the performance of the program. A ball screw with a good surface complete has excellent performance in rolling resistance, backlash, and put on qualities. Nonetheless, it is vital to improve the floor finish of a ball screw to attain precision movement, low wear, and lower noise. To accomplish this, unique wire brushes will be employed to polish precision-ground shafts.

For a ball screw to execute effectively, it must be tough, have a sleek surface, and retain lubricant. The floor complete of a ball screw need to be smooth, cost-free of cracks, and retain the lubricant properly. Cracks and annealing are both unwanted throughout the production procedure, so a top quality machine ought to be employed for its floor complete. For the duration of the production procedure, a CBN cutting insert with total spherical or gothic arch profile can be utilized to accomplish a high-good quality area complete.

One more finishing operation utilised in the manufacture of ball screws is lapping. Lapping enhances surface area top quality and journey variation. It entails sophisticated relative actions of abrasive particulates with the workpiece. This gets rid of a slim layer of substance from the workpiece, improving its surface quality and dimensional precision. The lapping approach can be carried out beneath reduced-pressure circumstances. It also boosts the friction torque and lubrication.

In lapping experiments, friction torque has the greatest affect on journey variation and surface roughness. A friction torque of about one N x m is optimum. In addition, rotational speed has only a small influence. The greatest mixture of these parameters is 1-1.5 N x m and thirty rpm. The bare minimum floor complete of a ball screw is close to 800 mesh. The smallest variation in journey is noticed at all around 50 percent-way by way of the vacation.

Lubrication

Suitable lubrication of ball screw assemblies is critical to preserve ideal efficiency and existence. Ball screw assemblies should be lubricated with grease, which is released straight into the ball nut. The lubrication port can be positioned at different places on the solution, which includes on the flange or in the external threads of the ball nut. Some ball nuts also feature a zerk fitting for less complicated lubrication.

The lubrication of ball screws is needed in the situation of working problems above 100oC. The minimal load for a ball screw is normally recognized with a preload drive. The lubricant is conveyed through the slender lubrication hole owing to the relative motion of the two surfaces. The elevated viscosity of the lubricant allows separation of the contact surfaces. To stay away from more than-lubrication, it is crucial to check out the lubricant stage routinely.

The oil employed in lubrication of ball screw assemblies can be possibly mineral or artificial. The oil is composed of mineral or artificial oil, additives, and a thickening agent, such as lithium or bentonite. Other thickening agents consist of lithium, barium complexes, or aluminum. The lubricant grade NLGI is a broadly used classification for lubricating greases. It is not adequate to select a particular kind of lubricant for a distinct software, but it offers a qualitative evaluate.

Even with currently being important to the functionality of a ball screw, lubrication is also important to its lifespan. Different varieties of lubricant supply corrosion protection. Prior to employing a lubricant, make sure to completely cleanse and dry the ball screw. If there is any buildup of dirt, it might harm the screw. To avert this from occurring, you can use a solvent or lint-totally free cloth. Lubrication of ball screw assemblies can tremendously extend the life of the assembly.